Machining

PIPE BEVELING

We can apply any type of Bevel to any degree required. Beveling can applied to the face of any size or diameter of pipe.

Why bevel a pipe?

Beveling of pipe or tubing is most commonly used to prepare the ends for welding. It can also be used for deburring the cut ends for safety and aesthetic reasons.

Subtract the pipe’s wall thickness from the pipe’s outside diameter. For example, if you had a pipe with a diameter of six inches and a wall thickness of two inches, you would subtract two from six to get four.

A PIPE END IS THE DESCRIPTION OF HOW THE SECTION OF PIPE ENDS.

Understanding pipe ends is important when designing a piping system since it would be inappropriate for the designer to specify a threaded connection for a large diameter pipe or to specify a welded end when connecting to a threaded component.

There are three main types of pipe ends: beveled, threaded or plain.

BEVEL END

A bevel is a surface that is not at a right angle (perpendicular) to another surface. The standard angle on a pipe bevel is 37.5° but other non standard angles can be produced. Beveling of pipe or tubing is to prepare the ends for welding. However, it can also be used for deburring the cut ends for safety or aesthetic reasons. Bevel End is abbreviated on drawings as BE.

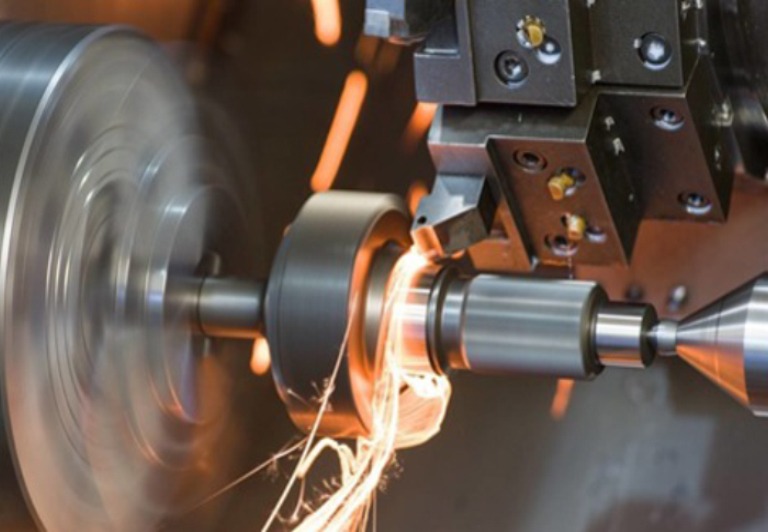

The beveling process is generally automated. This is because a pipe beveling machine can cut the bevel much faster than hand grinding, flame cutting or turning the pipe on a lathe. Further, the automated process ensures that there is an accurate and consistant pipe bevel each time. The automated process is much safer as operating personnel are not exposed to the same hazards as a person beveling the pipe.

This is the most commonly used end and is used on pipe, pipe nipples, and swage nipples.

THREADED END

Typically used on pipe 3" and smaller, threaded connections are referred to as screwed pipe. With tapered grooves cut into the ends of a run of pipe, screwed pipe and screwed fittings can easily be assembled without welding or other permanent means of attachment. In the United States, the standard pipe thread is National Pipe Thread (NPT). The reason for this is that as NPT connections are assembled, they become increasingly more difficult for the process to leak. The standard taper for NPT pipe is 3/4" for every foot. Threaded End is abbreviated on drawings as TE.

Threaded fittings have threads that are either male or female. Male threads are cut into the outside of a pipe or fitting, while female threads are cut into the inside of the fitting. As screwed pipe and fittings are assembled, two pieces are pulled together. The distance that is pulled together is called the thread engagement.

PLAIN END

Used to describe the ends of pipe which are shipped from the mill with unfinished ends. These ends may eventually be threaded, beveled, or grooved in the field.

A pain end pipe is a pipe that has been cut at 90° perpendicular to the pipe run. The reason pipe would be specified as plain end rather than beveled end is when the pipe will be used in a Socket Weld connection or for use with a Slip-on Flange.

ABBREVIATIONS

Common abbreviations for the types of pipe ends are as follows. In general, these are used to describe pipe nipples on drawings.

.jpg)